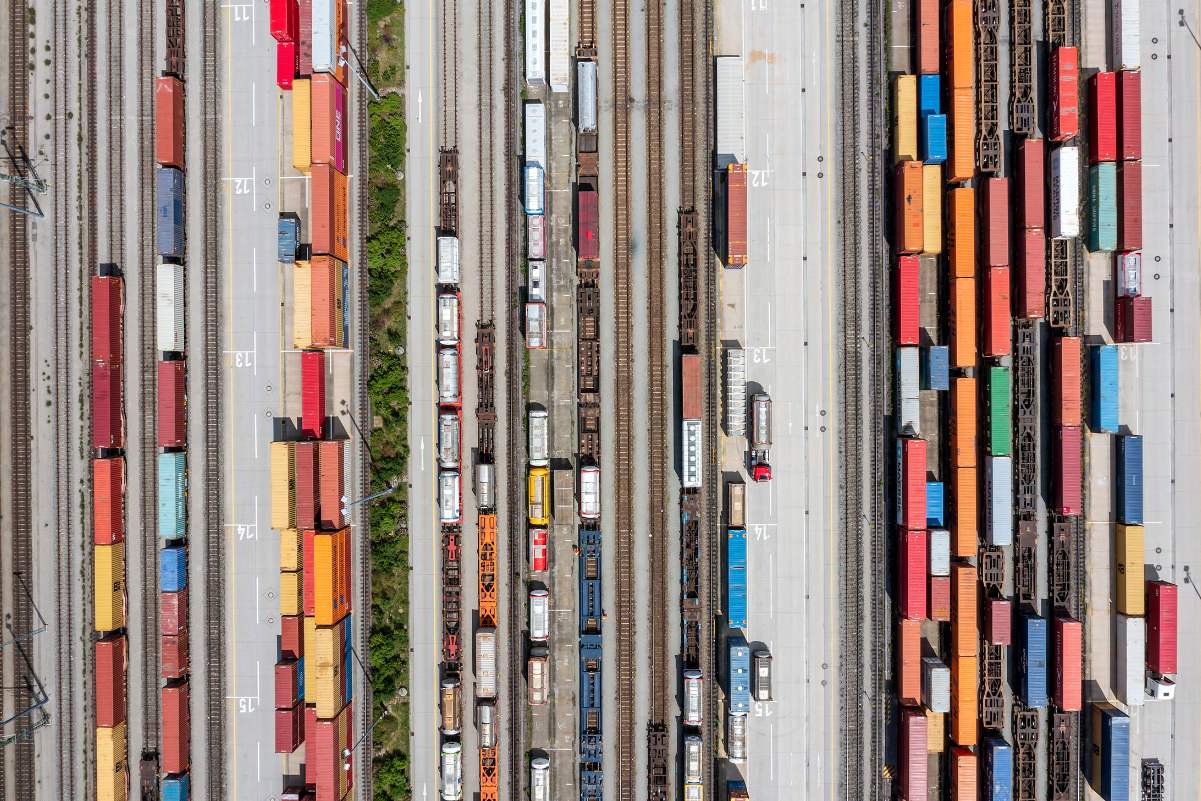

Reducing Greenhouse Gas Emissions with Inland Rail Terminals

The transportation sector accounts for approximately 25% of global greenhouse gas (GHG) emissions, with trucks and buses contributing over one-third of this total. As supply chains evolve to meet sustainability goals, rail transportation presents an opportunity to significantly reduce emissions, particularly through hub-and-spoke distribution models. This article examines how inland rail terminals contribute to lower GHG emissions and cost savings while offering a flexible alternative to other transport modes.

The GHG Intensity of Truck vs. Rail Transport

Long-haul trucking remains the dominant freight transport mode, but its emissions intensity far exceeds that of rail transport. On average, truck transport produces approximately 140 grams of CO₂-equivalent per ton-mile, whereas rail transport emits just 22 grams of CO₂-equivalent per ton-mile. The difference is stark, making rail infrastructure an attractive option for reducing carbon footprints while maintaining efficient goods movement. Leveraging rail solutions for long-distance transport can deliver significant emission reductions and help meet sustainability targets.

Hub-and-Spoke Efficiency in Freight Logistics

Unlike linear transportation models that rely heavily on long-haul trucking, the hub-and-spoke rail model leverages centralized distribution hubs where goods arrive via rail before being transferred to trucks for final delivery. This approach provides several advantages:

- Lower GHG Emissions – Maximizing rail transport over long distances significantly reduces the total emissions of freight movement, contributing to green logistics.

- Cost Savings – With fewer ton-miles traveled by high-cost truck transport, businesses see reduced fuel and logistics expenses.

- Scalability & Flexibility – Rail terminals can accommodate a wide variety of commodities without the regulatory constraints often associated with pipelines or dedicated infrastructure.

The Scale of Opportunity

In the U.S. alone, approximately 11.8 billion tons of freight are moved by truck every year, covering 331 billion miles and generating over 900 million metric tonnes of CO₂ annually. Shifting even 50% of this freight to rail could cut emissions by 380 million metric tonnes per year, a substantial step toward decarbonizing transportation. The opportunity to replace long-haul trucking with sustainable rail solutions is immense, providing businesses with the chance to reduce their environmental impact while lowering operational costs.

Looking Ahead: The Business Case for Rail Terminals

Beyond emissions reductions, inland rail terminals offer businesses enhanced flexibility and resilience in supply chain operations. Unlike pipelines, which face regulatory and environmental hurdles that can delay or halt projects, rail-based distribution hubs provide adaptable solutions for moving various commodities efficiently. Investing in rail systems and hub-and-spoke logistics allows businesses to stay competitive while contributing to a more sustainable future.

As industries seek ways to align with net-zero commitments, integrating rail infrastructure into transportation networks will be a key driver of sustainability. By investing in rail terminals and green logistics, businesses can achieve substantial cost savings while making measurable progress in reducing their environmental footprint.

About Us

Tri Innovations is an engineering consulting firm specializing in EPCM services, including rail engineering, design, procurement, fabrication, and construction. With extensive experience in industrial and passenger rail projects across North America, we help clients develop innovative transportation solutions that enhance efficiency and sustainability.

Our expertise spans planning, design, and execution, ensuring seamless project delivery from concept to completion. We are committed to building stronger communities by integrating sustainable infrastructure solutions. Contact us to learn more about how we can support your rail and logistics needs.